Protective clothing for welders - how to work safely in accordance with EN ISO 11611

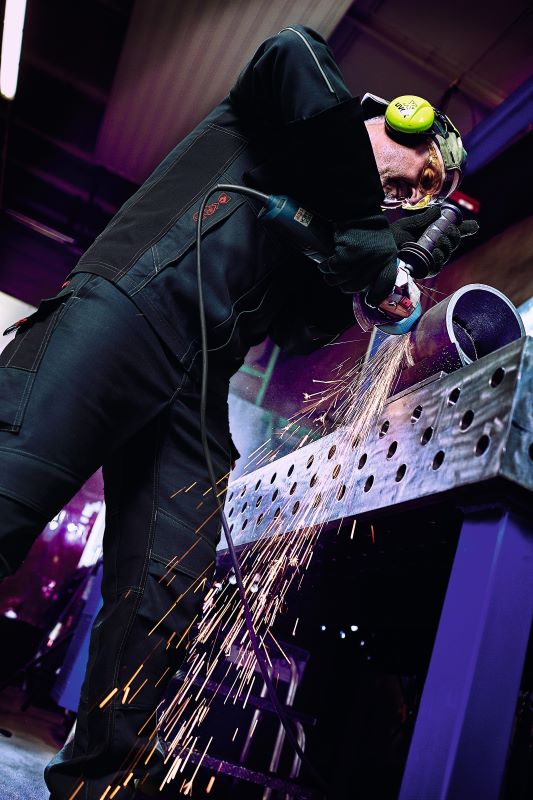

Welding creates numerous hazards, including welding spatter, intense radiant heat and brief contact with flames. Specially certified protective clothing for welders is essential for effective protection. The EN ISO 11611 standard defines the requirements for protective clothing for welders, which not only protects against thermal risks but also provides limited electrical insulation up to a DC voltage of 100 V.

High-quality protective clothing for welders is made of flame-retardant, resistant materials and includes jackets, trousers, aprons, gloves and protective bonnets. In addition to protection against external influences, wearing comfort also plays a decisive role, as ergonomic and breathable clothing significantly improves working conditions. Choosing the right protective clothing in accordance with EN ISO 11611 is therefore essential to ensure both safety and efficiency in welding technology.

In the following, we look at the dangers and show you how you can protect yourself in the best possible way with protective clothing for welders.