Industrial laundry in accordance with ISO 15797 - why the label is so important

The cleaning of workwear is an important topic for many industries. In this blog, we will explain what industrial laundry means and which standards and labels are used. For example, what is the difference between ISO 15797 and DIN EN ISO 30023? We will also answer the most important questions about the care of workwear and give you tips on what you should pay attention to when caring for and cleaning workwear and protective clothing.

WHAT DOES INDUSTRIAL LAUNDRY ACCORDING TO ISO 15797 MEAN?

What is the difference between DIN EN ISO 30023 and ISO 15797?

The symbols make it easier to identify textiles that are suitable for certain washing and drying processes, thus ensuring clear communication along the entire textile supply chain - from production to retail to the laundry. They include information such as maximum washing temperatures, recommended drying processes and dry-cleaning options that ensure the quality and functionality of clothing is maintained even after intensive use.

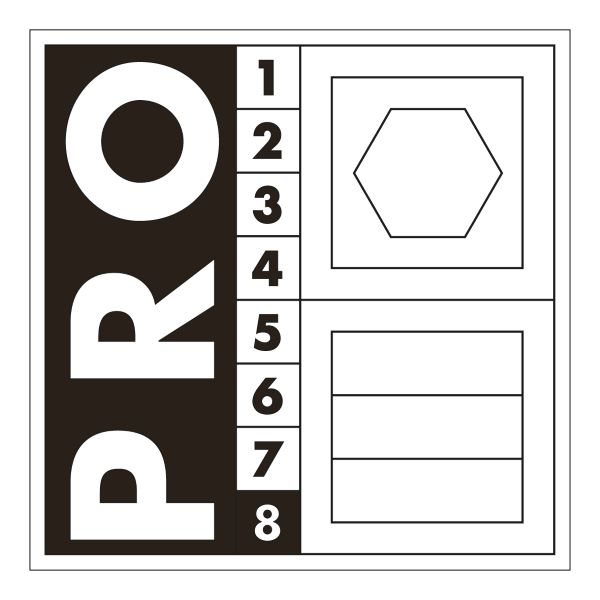

The PRO label for industrial laundry suitability

BP® products are predominantly labelled with the PRO label. The PRO label indicates that the labelled product fulfils the requirements of ISO 30023. It is tested for industrial laundry suitability in accordance with ISO 15797 in the washing programme (1-8), in the tunnel finisher and/or when drying in the tumble dryer.

On our BP® products you will find the Pro-Label symbol on our sew-in label, so that you can see which washing and drying process BP® has used to test the garment. For our PPE articles, the corresponding symbol is also shown in the manufacturer's information brochure.

However, the PRO label is not to be understood as care instructions. In principle, practical washing tests must be carried out before using any BP® product in industrial laundry.

This is how the "PRO label industrial laundry" pictogram is to be understood:

- The "PRO" lettering with a thick black background indicates suitability for care in professional laundries

- The series of numbers indicates which of the eight washing processes listed has been tested in accordance with ISO 15797.

- The two symbols on the right represent the drying process. The hexagon in the square stands for tumble drying. The rectangle at the bottom stands for tunnel or cabinet finishing.

Explanation of the PRO label

How do I recognise whether my clothing is suitable for industrial laundering?

At BP® you can recognise whether your clothing is suitable for industrial laundering by explicit labels such as the PRO label. The picture on the left shows the sewn-in label of a BP® tunic. It shows:

- Washing (washing tub) at 95 °C. It shows the maximum washing temperature in the normal wash cycle in degrees Celsius.

- Drying (square): Dots within the square indicate the permissible drying intensity: one dot means tumble drying possible (gentle drying up to 60° C) .

- Bleaching (triangle): The triangle indicates whether the garment may be bleached. An empty triangle means ‘Chlorine or oxygen bleaching permitted’.

- Ironing (iron): The iron indicates whether the garment may be ironed and at what temperature. Dots under the iron indicate the maximum ironing temperature (two dots means ‘iron at moderate temperatures up to 150° C’).

- The capital P stands for ‘Professional dry cleaning normal process’.

The PRO label is also shown on the label. The PRO label indicates that this garment fulfils the requirements of ISO 30023. It has been tested for industrial laundry suitability in accordance with ISO 15797 on wash programme 6 (= white workwear and/or coloured trimmings, hydrogen peroxide). The rectangle on the right stands for the drying process ‘tunnel or cabinet finishing’.

Explanation of the care instructions on the sew-in label

Conclusion - How companies benefit from ISO 15797

The ISO 15797 standard was developed to support manufacturers, suppliers and laundries in evaluating and labelling workwear with regard to its suitability for textile service.

Workwear that is certified according to ISO 15797 proves its robustness and resistance to the extreme conditions of the washing process without losing its colour and shape. This durability is of central importance for the longevity of the products, as it has a decisive influence on how often companies have to purchase new workwear.

This has a positive economic impact for companies, as the long-lasting quality means that less money needs to be invested in the purchase of new workwear. This relieves the company budget and creates financial leeway for other important aspects of the business. Find out more about BP's sustainable workwear here.

Cleaning workwear - industrial laundry suitability according to ISO 15797 in the video